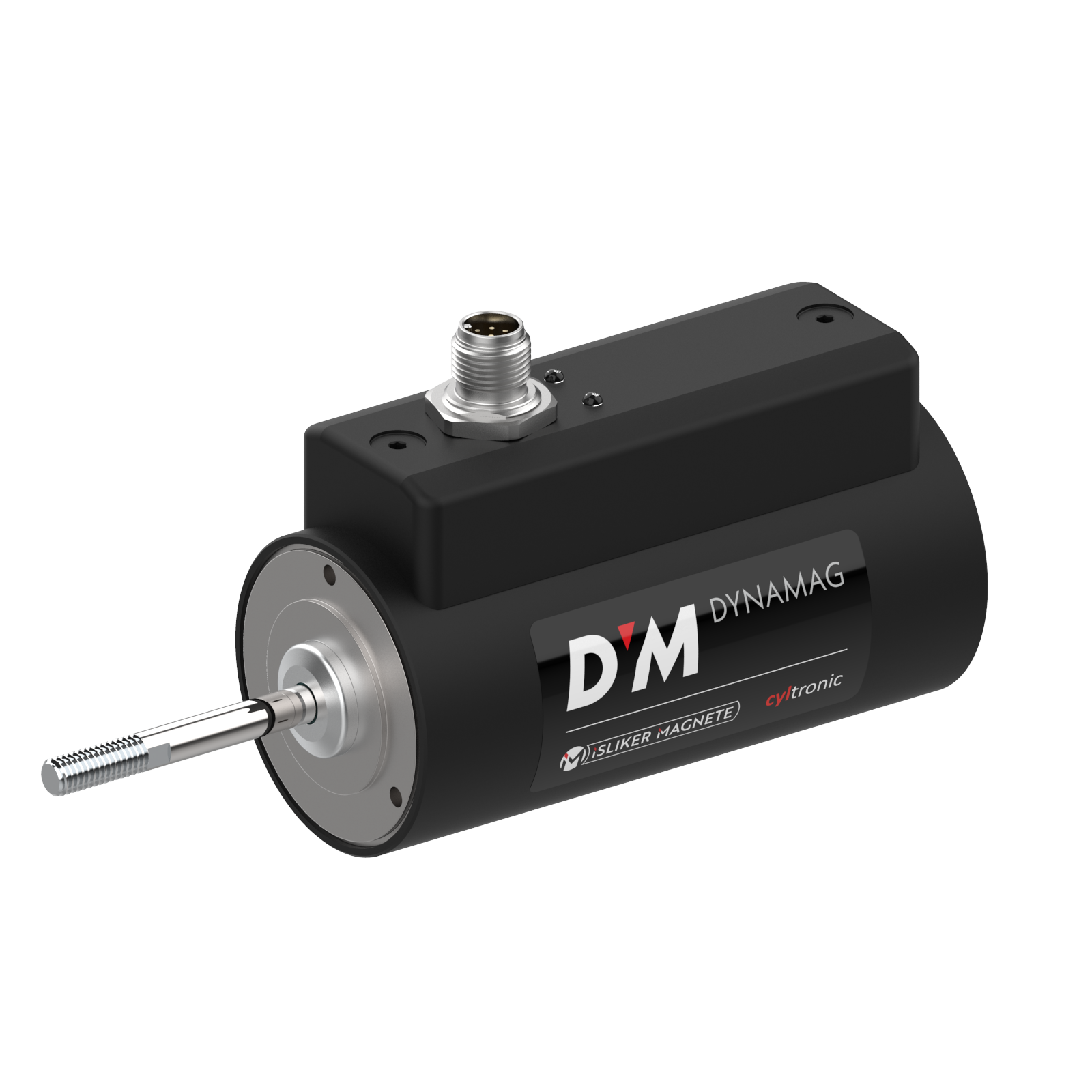

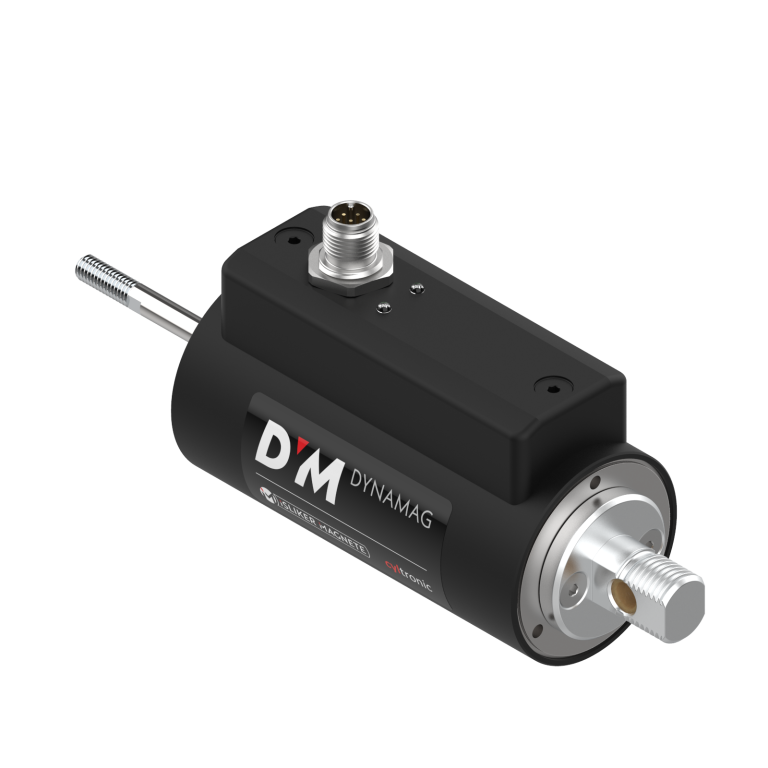

The DYNAMAG is a dynamic linear solenoid for short-stroke electrical

applications in mechanical engineering.

- Electric short-stroke movements straight forward: High forces with minimal energy consumption, without overheating.

- Fast processes made easy: High number of cycles through electomagnetic drive concept.

- Effortless integration: Single cable for power supply, control signals and end position sensors.